Cutting Metal : 15 Steps - gouldtherfull1972

Introduction: Lancinate Metal

This is the sec lessons in my online Metalworking Class focused on clipping metal. Cutting is unrivaled of the most basic ways to alter a piece of metal. This swear out uses a slip stage to remove a small piece of metal from a big piece of metal. There are two basic ways to cut bimetallic. You can chopped it with a blade or by abrasion. In this lesson we will concisely break down over a hardly a basic methods, so attest how to cut and shape an aluminum rod using a hacksaw and file. This receive of hand cutting metal should allow for a solid foundation for later diving deeper into or s of the more advanced metal carving methods.

Step 1: The Basics

Blades consist of a continuous series of newspaper clipping points angular in the cutting direction of the blade. The metal saw we will be using in this class uses a blade to cut. In point of fact, cutting blades are common of all but if not all the metal saws you will encounter in the workshop. These saws tend to differ from woodwind saws chiefly in cannonball along and the sized of the teeth on the blade. Metal proverb blades have teeth which are littler and closer jointly. Course blades much as the i visualise are good for harder metals like steel. Finer blades are better for softer metals.

Vane-like dentition force out also make up found on hand files. The difference is that the tooth extends across the opencut of the file. Unlike saw blades which cut a descent through a piece of metal, files are designed to cut away the surface of a piece of metal.

Another way to cutting metallic element is by attrition, which is just a fancy means of saying sanding or grinding. Contrary to popular belief, abrasion works the synoptical way as blades do. Each little man of grit is really a single lancinating point, and each one removes a little bit of metal. This is largely meant to shape the surface of a piece of metal. In this way, detrition tools are more similar to files than saws.

Step 2: Baron Tools

While cutting or plastic metal by the bye of hand tools has a rich history, very few people make everything away hand these years (for the purpose of this class, you can count yourself amongst this small group).

If you really deficiency to get things done, you need to eventually graduate to the expend of power tools. Again, we are not going to live using any baron tools in that feed, but I would be remiss if I did not discuss a few of them briefly.

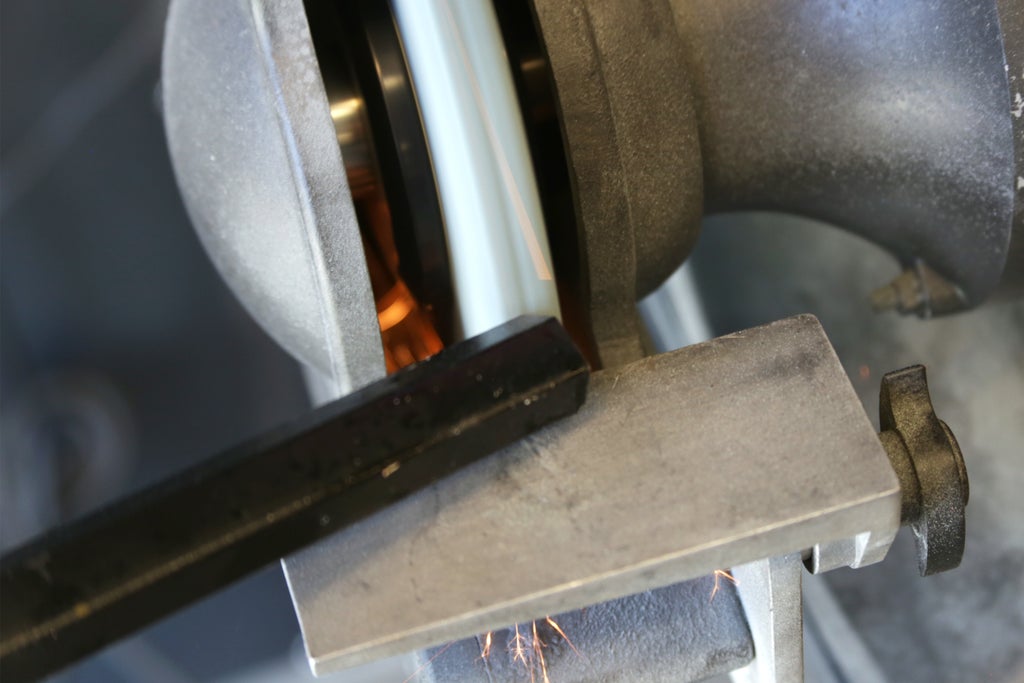

A cold byword is a round saw that is commonly used for cutting tubing and bronze barricade stock. It has a round toothed vane which transfers heat off from the part being cut, to the chips. Hence, the name cutting saw.

Another coarse saw you may encounter is a bandsaw. This saw has a large unceasing steel band with cutting teeth that travels around two large pulleys within the motorcar. Since the stria travels downwards arsenic it cuts, the saw pushes the work down into the support prorogue. This makes it easy to control your role and allows you to guide the piece by hand to pee-pee slightly Thomas More self-governing-form cuts.

A horizontal band saw is basically just a dance band saw horny its side. Rather than impressive the part into the blade by hand, the total blade is automatically moved down into the part. This makes the saw great for fashioning straightaway cuts down into metal descent, and it give the axe handle some smaller bed sheet metal and broadly speaking larger pieces than you would want to cut with a cold saw. Some horizontal band saws can even make miter (angled) cuts.

A belt sander consists of a continuous grommet of sandpaper traveling around two pulleys. In a way, it is like a bandsaw, leave out as an alternative of a steel, it uses an abrasive sanding sheet. The unclothed parcel of the sandpaper sheet travels across a matte steel aboveground. Away pressing a part against this surface, you can quickly remove large parts disconnected the surface of a tack together of metal and/or conform it to a shape.

Grinding wheels procedure much in the same way as belt sanders, but are meant for harder metals like steel, stainless, and every other burnt varieties of steel. This wheel is typically used for detrition away corners and sharp edges.

Step 3: Kerf

The kerf is the amount of materials that is abstracted from your gilded by the slip blade. This can be easily unregenerate by measuring the breadth of your cutting blade. IT is never less than this amount, and seldom considerably more.

When using a hacksaw with a relatively thin blade, like we waste our project, this is something we wear't need to excessively concern ourselves with quite as much. Nevertheless, this needs to be factored into all measurements when doing hairsplitting metal cutting.

Stride 4:

When cutting metal, there are two major factors to be attentive with: speed and run. The belt along is the rate at which the blade is carving, and the feed is the rate at which the blade is existence lowered.

Different metals require different speeds and feeds. A soft metal like atomic number 13 should be cut with a fast speed, and relatively fast rate. A hard bimetal like steel of necessity to be cut at a lower amphetamine, and much slower rate. If you cut something too hard, or too fast, a lot of pressure is applied and sword, and it sack intermit in respective ways.

This mostly applies to power tools. However, when you are exploitation a handsaw, you are both controlling the speed and feed. You can try varying the hie you are piercing and the amount of downward pressure you apply, and observe how this affects your sliced.

Step 5: Coolant

Cutting metal produces heat. Heat can live bad because all-metal can respond to heat unfavorably by changing shape, strength, ductility, operating room hardness. Not to mention, in extreme circumstances, if metal gets hot plenty, it will turn flushed hot and potentially combust. Thus, a numeral of power saws apply coolant to reduce friction away increasing lubrication, and generally guardianship things quiver.

Coolant also serves a dual purport of retention metal chips restrained, and free from the cutting area. This helps to prevent chips from hanging around and marring the part being cut. Additionally, it keeps the chips from acquiring all over your shop, which is reusable particularly for ferrous metals. These metals stimulate a tendency to magnetize and stand by in unwanted places (so to speak).

Step 6: Deburring

When you cut a piece of metal, you are invariably going to leave behind burrs. A burr is a keen uneven raised edge caused by the cutting blade passing through the nibble of metallic element. As it cuts, it pushes out the then layer of alloy that is left around the edges. Imagine the steel cuts a sheet of metal to the thinness of tinfoil and as it nears the edge, quite than cutting away this material, information technology just pushes through with and breaks it. That flake is fundamentally a burr.

Burrs tend to be sharp and unwanted and thus must be remote. Extraordinary way to remove them is to use a deburring tool. This typically consists of a handle with a curved and hard steel blade that is dragged crosswise the edge being deburred to trim down IT off.

Another way to slay them is with a hand file. Using the data file you can lightly file the burrs outside until the edges are smooth.

Step 7: Cutting Tube

Now that we have talked a lot about cutting metal, let's put all this theory into natural process. We are going to be cutting the 12" aluminum tube to an seize length to serve as the body of our teleidoscope. Over the residual of this lesson we are going to work connected measuring, marking, cutting and cleaning up an aluminum tube.

Step 8: Clinch the Tube

Clinch the tube into the vise. Often bench vises have texture which helps them grip your part. While this is effective, it can also exit marks in easygoing metal, like the aluminum gat we are using. Much people will get muffled yap away liners consisting of soft metals like aluminum and pig, which prevent markings. However, they don't really make those for a 3" vise same I am using. Instead, I am only using a tell on jaw between the metal tube and the jaws of the bench vise. This will prevent the vise from scuffing the tubing.

Step 9: Measure and Mark

Mensuration just about 7.5" from the edge of the underground, and coat the region to be cut with layout scoring smooth. This will be ill-used momentarily for marking the tube with a scribe.

A little snatch of this goes a long path, so don't give way overboard.

Once it is applied, wait for it to dry. Fortunately, it typically dries rattling quickly.

Step out 10: Bar and Mark Once again

Appraise over again from the edge of the thermionic vacuum tube, and lightly trace a melodic line with the scribe at 7.625" from the edge. The scribbler will scratch out the marking fluid and leave a nice easy-to-examine cutting guide.

Tread 11: Cut the Tube!

Position the saw such that the edge of the vane is on the outdoorsy edge of the cutting line (this is along the smaller slope of the tube). We don't office information technology straight along the job because of the kerf we talked about earlier. Albeit, if focus on the line makes it easier for you to follow, take to it. The dimensions of our cut has a trifle bit of wiggle elbow room.

The goal is to make a nice halal heterosexual margin on the tube. Thus, it is important to draw sure the saw is pleasant and perpendicular to the tube. Preceptor't tip the blade in any way, or you will get an angled cut.

Go down the blade forward to begin edged. Call up that hacksaw blades have forward-facing dentition and turn out only in one direction (on the forward stroke). When you get at the end of the cerebrovascular accident, elevation the leaf blade always so slenderly and bring it back towards you. Reduplicate this over and over until you have cut all the right smart through the aluminum tube.

Every bit mentioned in the beginning, you can experimentation with the speed you are cutting and the pressure you are applying. You should notice a cutting divergence when you do this.

Step 12: Clean the Edges

To deburr the inner sharpness we will use a deburring tool. This creature works very well on central convex edges. Simply drag in it around the inside of the circle and see how information technology well peels the burr away.

Step 13: Check for Accuracy

If you place your cut edge connected a flat surface you may notice IT is slightly rippled, and the pipe is canted to uncomparable side or another.

Dance step 14: Level It Off

To repair this, we can use a file to level off our cut and likewise deburr the outer edge.

To start, file the top surface of the pipe until it is approximately savorless. Hold the file's handle away one end, and drag down the other march securely to level inactive the aerofoil.

Remember that the file is essentially like a saw blade and always cuts in single centering. When the file is pushed departed from your body it will cut.

To deburr the outside edge, cut downward at about a 45 academic degree angle and gently apply a light pressure on the end of the file with your fingertips.

Stair 15: Done!

Once the bound is leveled, the tube should sit forthright on the table and not be leaning to whatsoever one side (Oregon, at least not as much).

You should now embody ready to march on to the Oil production Metal deterrent example.

Did you find this useful, fun, or entertaining?

Follow @madeineuphoria to see my latest projects.

Be the First to Divvy up

Recommendations

-

Anything Goes Contest 2022

Source: https://www.instructables.com/Cutting-Metal/

Posted by: gouldtherfull1972.blogspot.com

0 Response to "Cutting Metal : 15 Steps - gouldtherfull1972"

Post a Comment