How Do You Measure Muzzle Loader Patch Size

To achieve the virtually reliable results from your testing you volition demand to be as consistent every bit possible in every particular of loading and shooting the rifle. Shoot your test targets from a stable bench rest. Use sandbags, front and rear rests in order to eliminate human error as much as possible. Be consistent in how you concord the rifle, where you lot place the rests or numberless in contact with the burglarize, every bit well as your sight picture and trigger control. Don't try to shoot your test targets from off-hand. There will be a time to do shooting from field positions but it is not during your load testing.

Exist as consistent equally possible in how you lot load the burglarize. Measure your pulverization accuse by slightly overfilling the measure and scrape off the excess with the back of your knife or other straight edge. Practise non tap or shake the measure. That will crusade the powder to settle and inconstancy in the amount of pulverization the mensurate will concord.

When seating the brawl down onto the powder charge use the same corporeality of pressure on the ramrod each and every fourth dimension. You lot want to seat the brawl firmly, without crushing the pulverisation kernels. Consistent pressure on the pulverization produces a more than consistent burn rate and amend consistency in your velocities from shot to shot. Information technology'due south best to use a metallic, range type ramrod of brass or steel with a cage guide when loading for demote shooting. Do not bounce the ram rod or hammer on it to seat the ball. Doing so deforms the brawl and out of round balls may not fly truthful.

Utilize the smallest targets you tin meet well. Set your targets from 25 to fifty yards depending on the size of your target and how precisely you lot tin aim. Don't be concerned about sighting the rifle to hitting center of the bull'south eye. All yous need at this fourth dimension is to proceed the groups on the paper. Yous will fine tune your sights after you have found the nigh authentic load. If possible, consider temporarily mounting a adept peep sight or scope on the rifle for shooting these exam targets. The better you tin can meet your target and sight alignment the better your results will be. If you are not able to mount either sight system on your rifle remember to keep your vision focused primarily on the front end sight.

After you have discovered the best load for your burglarize, I recommend adjusting the sights to put the center of your groups on the balderdash's eye by shooting from the bench residual. Some shooters volition contend that it's all-time to sight in by shooting from off-hand positions. I disagree, I believe doing that hides the homo mistake in shooting off-hand. Past sighting from the bench, any error in your stance, posture, or how y'all concord the rifle volition evidence on your target assuasive you to brand corrections and perfect your off-manus shooting. Remember, any deviation of angle in your shooting is multiplied by the distance to the target. A modest miss at close range becomes a huge miss at longer range. Perfecting your off-paw shooting skills greatly increases your effective range in the field.

Internal condition of the bore.

It is very important that you wipe the diameter of the butt between shots with a dry out or slightly damp cleaning patch during all this test shooting. The reason is to keep the bore in the same status for each and every shot. If you neglect to do this fouling builds upward with each consecutive shot. Equally the amount of fouling increases the friction increases, internal pressures go up, the velocities become upwardly, and each shot strikes higher on the target than the last. A vertical string up volition show on the target.

You don't desire to really clean the barrel between shots, merely wipe away the excess fouling in order to maintain the aforementioned amount in the bore for every shot. I prefer to run a dry out cleaning patch down the barrel and dorsum out just once later on each shot. If your cleaning patches are too tight to pull back out of the barrel dry out, you can moisten them slightly. Simply it is difficult to apply a consistent amount of liquid to each patch so the better method is to decline the size of the cleaning jag to make it smaller. The easiest way to exercise that is to chuck your cleaning jag in an electrical drill and file it smaller as you rotate it. I prefer to go my cleaning patches from the same source to insure constant size and thickness. This insures I am leaving the same amount of powder residual inside the bore for every shot. You can purchase cleaning patches or brand your ain from cotton wool flannel fabric and cutting information technology to size with a rotary cutter.

Sort the balls by weight.

The showtime variable we need to go command of is the weight of the circular balls. Utilise a reloading scale and counterbalance each ball from a box of 100. You lot will observe that some are much lighter than the heaviest. If the balls are nonetheless size, this should tell you that there is an air bubble in those lighter assurance. Unless that void happens to exist in the exact center of the ball it will exist out of balance. Those out of balance assurance are going to wobble in flying to the target. The lightest balls of class accept the largest air voids. Those out of balance assurance volition strike outside the grouping producing a flier on your target. If you don't eliminate the fliers past sorting them out with the scales, any further load testing is going to be in vain. Check the size of the lightest and the heaviest ball with your punch micrometer. If these measure out the same diameter yous have again confirmed the presence of a void in that lighter brawl.

When sorting assurance past weight I similar to separate them into groups that counterbalance exactly the same to within 1 tenth of a grain. I use the heaviest groups of balls for load evolution and serious competition on paper targets. The mid weight groups are fine for hunting or shooting metal gongs in competition. The very lite assurance either go back into the casting pot or get used for plinking.

If target shooting for score on paper targets does not interest you, latter on you tin salve some fourth dimension and effort by sorting the assurance into two groups. Practice that by setting your scales to one and a half grains lighter than the heaviest ball. So as you weigh each ball, put those which weigh heavier than that setting into 1 group and those which weigh less into another grouping. This is a quicker fashion to dissever the air chimera, lightweight out of residue balls from the heavier assurance which are more stable and fly true.

You won't notice much difference in your group size when shooting offhand or hunting with assurance that weigh within 1 and a half grains of the heaviest one. Those balls in the lightweight group tin still be used for informal plinking. Regardless of which method yous finally decide upon, your bench rest shooting and load development work should be washed with balls that weigh within ane tenth of a grain from each other. Yous want to know that any difference in the size of the group on your test target is the result of the variable yous are testing and non acquired by a ball that was a half grain lighter or heavier than the others.

Most shooters agree that hand bandage balls are more than consistent in size and weight than swaged balls. If you are using cast balls be sure to position the sprue upwards and centered when you lot seat information technology into the muzzle. If yous load the ball with the sprue to one side information technology will wobble and wing outside of the group. Swaged balls lack a sprue and so this won't be a concern. If you lot elect to use swaged assurance purchase them from a undecayed source and then you will always have a reliable supply.

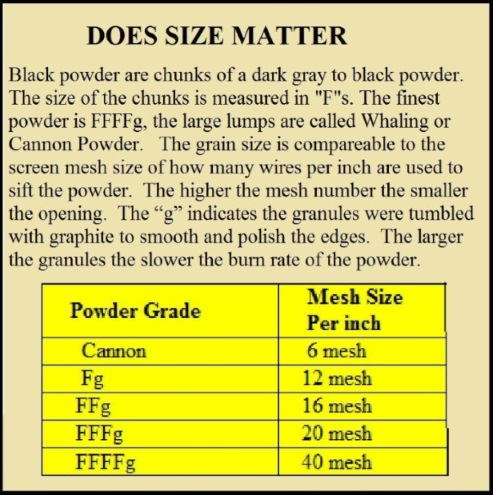

Cull the proper granulation of powder

Current wisdom suggests that 3-F granulation black pulverisation is best in rifles of 45 caliber and smaller and 2-F granulation is better for 50 caliber rifles and larger. This is not a difficult and fast rule and many 50 quotient rifles will shoot best with 3-F granulation powder. Y'all will examination that latter. For your initial testing start with those recommendations. Mensurate your powder using an adjustable powder measure. Do non counterbalance out the powder charges on a scale. Black powder measures more consistently past volume.

Fix your adjustable mensurate for an amount in grains equal to the caliber of your burglarize. For our fifty caliber rifle that translates to 50 grains of blackness pulverization. Slightly overfill the measure and scrape abroad the excess level with the elevation. I adopt the type of measure with an fastened spout for target shooting. The spout levels off the pulverisation accuse when information technology is turned back into place after filling the measure out. Do non tap or shake the mensurate. Doing then causes the powder to settle and meaty making it near impossible to achieve consistency with the amount of pulverisation in the measure.

Adept patching fabric is one hundred pct natural fibers. Synthetic fibers volition cook when y'all burn down the gun and leave a mess in the bore. Neither is conducive to accuracy. Y'all want cotton, or linen fabric with a tight weave. Pillow ticking is a practiced choice to begin with. Become to your local fabric shop and purchase near a eighth or a quarter yard. Run information technology through the washing machine offset to remove whatever starch or sizing. Cutting your textile into strips just a little wider than the burglarize muzzle. Apply spit, or black powder cleaning solution (moose milk) for lubrication. Use but enough to dampen the patch.

Now you are ready to take the heaviest balls y'all have weighed and your pillow ticking strips to the range and start testing powder charges by shooting off of the bench rest. Clothing middle and hearing protection! Use sandbags and a practiced steady front and rear rest. You want to eliminate any stray shots that might be acquired past homo mistake. Set your target at 25 yards and fire a shot or ii to run across if yous are striking on paper. If not, postal service a larger target or move the target closer until y'all are striking the paper. If needed move the sights until your shots are on the target. Information technology isn't necessary to sight in on the bull'southward eye at this indicate, you lot just demand to get the groups somewhere on the target.

Finding the best pulverisation charge

With everything prepare and later on confirming that your shots are striking on the target yous are set up to begin testing. Mail service a new target. Wipe the bore after each shot to remove excess fouling. Set your powder measure at fifty grains. Fill the measure, level it off and pour it down the barrel. Moisten your patching strip with saliva by placing it in your mouth or spray a little of your cleaning solution or moose milk on it. I always run out of spit and then I prefer to spray it with moose milk. Lay the patching beyond the muzzle, place a ball on it sprue upwardly and centered if it has one, put the short end of your starter on the ball and requite it a whack with the palm of your manus. Cut off the patching with your pocketknife or scissors. Seat the ball further down the barrel with the long end of the starter then seat it onto the powder accuse with your ram rod. Shoot the target. Repeat the wiping, loading, and shooting until you accept five shots on the target. Call back that target and write on it the powder brand, granulation size, and amount in grains. Record the ball size and weight along with the patching material and lubricant used.

Mail a new target and increase the powder charge by five grains. (Two grains for pistols and modest caliber rifles) Do not modify any other component of the load. Continue shooting five shot groups on the targets, increasing the powder charge by five grains for each target until you reach the maximum charge recommend by your rifles manufacturer. For safety and to avert damaging your burglarize do not exceed the maximum load recommended past the manufacturers of your rifle. Be sure to tape all information on each target.

When yous have finished shooting you volition have 10 to twelve targets with five shot groups on them. You will notice a pattern developing in the size and shape of the groups. Usually each grouping will become tighter and smaller equally you lot increased the powder accuse. At a sure indicate the groups will began to open up again and grow larger. Select the target with the best group. In that location, written on that target, is the most accurate pulverization charge for that burglarize.

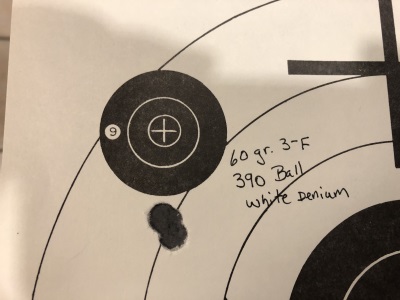

This is the first 5 shot target from my 54 caliber percussion rifle at the beginning of the load development process. It was shot with weight sorted balls, pillow ticking patching and Moose Milk lube

.

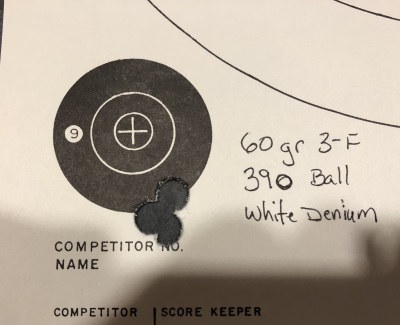

Here is the final 5 shot target after compleating this procedure.

Patching material

Now go downward range and pick up as many of your fired patches as you can find. When you study these fired patches you lot will notice several things. They should all exist perfectly circular and they will accept a black ring in the heart. If the patches are torn, cutting, or shredded, or you see that the pulverization burned through the fabric your patching material is too thin. Another sign of thin patching is burning inside the black ring on the side of the patch that was in contact with the ball. That is a result of the brawl slipping out of the patching under the pressures of the burning gases and yous need thicker patching material. If you find cuts in the patching material where the patch is compressed between the ball and the lands in the diameter, it is commonly a sign of sharp edges that remain on the lands from the rifling process. This occurs more than often in production built rifles. Custom made barrels are finished much smoother and commonly hand lapped before leaving the shop. In whatsoever event, those sharp edges will usually polish out on their own after a hundred or and then shots have been fired.

If your diameter is particularly rough it may need to be polished smoothen by hand lapping. You can accomplish this by using JB bore paste on a tight cleaning patch. Employ your metallic range rod with a bore guide / muzzle protector and polish the bore according to the instructions that come with the JB bore paste. Extremely rough or neglected barrels may need to be polished out with valve grinding compound. However, this is a desperate measure out that may salvage a badly neglected barrel but should only exist done as a concluding resort. In this case one is better off to supercede it with a new barrel.

Selecting the best patch thickness

Now that you have found your best powder charge you are ready to test different patching materials. You lot volition demand a micrometer for this. Use the micrometer ratcheting handle and mensurate the thickness of the material y'all used for patching. Practice taking measurements on unlike places on your strip of material until y'all are getting consistent measurements. Allow us assume that yous are getting measurements that bear witness your fabric to be .015 in thickness. That would exist the thickness of the fabric before it is compressed between the ball and the lands in the bore of your butt. Fabric using a tighter weave or heavier threads will shrink less than fabric with lighter thread or looser weave.

Mensurate your patching strip over again merely this time instead of using the ratcheting handle of the micrometer which is designed to skid at a sure pressure level, grasp the handle with your pollex and forefinger at a point other than the ratcheting office of the handle and apply as much pressure on the fabric equally you tin can using only your thumb and forefinger. You will notice that the cloth compress to a much thinner measurement now. This is what we call the compressed thickness of the material. And this measurement is the one which is critical to the accuracy of a muzzleloading rifle.

If, every bit nosotros assumed earlier, your material measured .015 in its uncompressed measurement yous likely found that it compress to a measurement of .008 or perchance even thinner. If you were to measure a different textile you lot could very well discover that it also measures .015 thick uncompressed but that its compressed measurement is .010. Why is the compressed thickness of this fabric different than that of the other fabric? Considering the fabrics consist of thread that varies in size, has a tighter weave or perhaps both weather condition exist.

This compressed measurement is critical to accuracy in muzzleloading rifles. A thousandth of an inch in patch cloth thickness can be the departure between a load that shoots very tight groups and i that looks more than like a shotgun pattern. Several factors determine the best thickness of cloth needed for your rifle to shoot its best groups. One of these is the depth, width, and shape of the groves in your barrel. A butt with vii grooves in its bore will have narrower grooves and lands than a barrel with vi groves provided the bore is the same caliber. The bottom of the groves might be foursquare or rounded. The depth of the groves volition vary. Some rifle barrels have shallow grooves while others will have much deeper groves. Also consider that barrel groves made on the same machines will vary slightly in the depth of the groves every bit the tooling wears down. No wonder and so that an authentic load for one rifle butt may not shoot well in another apparently identical barrel. And we oasis't however considered the different rates of twist used by different barrel makers.

Rate of twist in the rifling is expressed in the number of inches a brawl must move through the butt in order to complete one full revolution. A barrel made with a 1-60 twist charge per unit means that the brawl will demand to laissez passer through 60 inches of that barrel in order to complete one full rotation. A barrel with a ane-20 twist rate means that the brawl will consummate 1 full rotation inside 20 inches of that barrel. The best twist charge per unit will depend on the size, shape, and weight of the projectile equally well every bit its velocity.

Fortunately for the states shooters the barrel makers have done the math to determine the best twists. Unfortunately, nosotros don't have much choice in the matter. Production rifles may allow shooters to choose between twist rates which are all-time suited for round assurance or i that volition better stabilize bullet shaped projectiles. Custom butt makers usually provide a few more than options. The best we can do equally shooters is to consider whether nosotros intend to use our rifle for hunting and the college velocity loads necessary for that or for lucifer target shooting with slower, lighter loads and lodge the appropriate twist in a custom barrel. Otherwise we are going to have to use the compromise twist in nearly product rifles.

The patch material has two important functions. I is to grip the ball tight enough to impart spin to it. This gyroscopic spin is what stabilizes the ball in flight and why a burglarize is so much more authentic than a smoothbore gun. The other important function is to act as a seal for the expanding gasses that send the brawl on its manner to the target. If the patching material is too sparse or also light the ball will jump clear of the patch before it exits the muzzle or the hot gasses volition burn through the patch, past the ball, and push it off course as information technology exits the muzzle. Considering of all the variables in size, shape, and depth of rifling grooves previously mentioned information technology is impossible to predict the thickness of patching material necessary for the most accurate load in whatsoever rifle. Ideally we want a patching material thick enough to fill the depth of the groves in our butt and grip the ball firmly in the patch to go on it in that location snugly until it exits the muzzle. We also need that material thick enough to withstand the heat of those burning gases without burning through and allowing a gas leak to blow by the ball.

Fortunately, you now have a method to accurately measure the compressed thickness of fabrics and I am going to explain a systematic method to permit yous to find the best patching material for your particular rifle. Take your micrometer to the textile store and look for materials that when compressed, measure a thousandth inch thicker than what y'all were shooting. Ticking, muslin, denim, or linen are all good as long as these are i hundred percentage natural fabric. Read the label on the commodities, a lot of denim and lately even some ticking contains polyester. Yous do not want that. Cull fabrics of several different thicknesses up to about .022 (sometimes even thicker material is required for rifles with deep grooves) Try to notice materials in increments of i thousandth of an inch autonomously and purchase the smallest corporeality the store will permit. Typically, an 8th of a yard. I like to marker the label on the bolt of the fabric with my initials to help identify it when I go back to purchase more. At to the lowest degree salve your receipt so you can become the same fabric that shot best from your rifle when your return to buy more.

Cutting some strips out of each sample of fabric and mark them on the finish with the measurements. Then go dorsum to the range and shoot some more than 5 shot targets with each thickness. Use the best powder charge from your previous range session, the balls you sorted by weight, and the same lube. The just matter you lot want to change most your load is the patching. Starting time with the fabric you used previously then get to the next thickest and and so on. Be sure to write on the targets which sample was used along with all the other data you have recorded on the previous targets.

You volition notice the groups getting smaller and tighter every bit the thickness of the fabric increases. Continue to use thicker material until the load becomes and then tight that you must employ a mallet to start it downwards the barrel. When the load becomes that tight and you have to pound the ball out of shape to seat it your groups volition begin to open again. At present compare all your targets and the one with the best group will show you which cloth thickness is correct for your rifle and that detail size brawl.

Selecting the about authentic size brawl

It is a good thought to repeat this test using unlike size balls. In our instance of a l caliber rifle, balls are bachelor in sizes .480, .490, and .495. Y'all may find that your rifle is virtually accurate with a combination of a smaller brawl with a thicker patch or a larger ball with a thinner patch. Be certain to sort all those balls by weight. You don't want to miss place a fantastic load because of a lite weight ball. When you take completed this stage of your testing you will have the information necessary to select the most accurate powder charge, ball size, and patch thickness for your rifle.

Time to think and make some choices

At this point y'all have some decisions to make. If your goal is strictly match target shooting you lot tin select a tight loading combination of patch thickness and ball size. Even if you must utilize a mallet to first that load into the muzzle. If that tight plumbing fixtures load happens to be the 1 that puts all five shots into i hole not much larger that a single ball, use the mallet!

At present if target shooting is going to exist your main matter go back and test your powder charges again, this fourth dimension starting with 50 grains and going down by five grain increments. It doesn't take a powerful load to punch a pigsty in a paper target and many rifles will shoot outstanding groups with very light loads. One of my fifty quotient rifles shoots its smallest groups with 30 grains of 3-F Goex powder.

However, if you intend hunt or shoot trail walk type of events that require loading from a shooting pouch you may need to accept some amount of compromise betwixt accurateness, ease of loading, and adequate power / velocity necessary to make a humane kill of your game. Personally, I am willing to surrender some corporeality of accuracy in favor of a more powerful load needed for hunting and 1 I can load without needing a mallet to start the brawl. This doesn't necessarily mean you demand the heaviest pulverization charge your gun tin can handle to kill game. One of my 50 caliber rifles puts the brawl completely through whitetail deer with a load of only threescore grains. In making this conclusion you now have reliable data recorded on all those targets to guide you. Choose your all-time load according to these considerations and the groups on the targets and so become purchase enough of that fabric necessary to last a good long while.

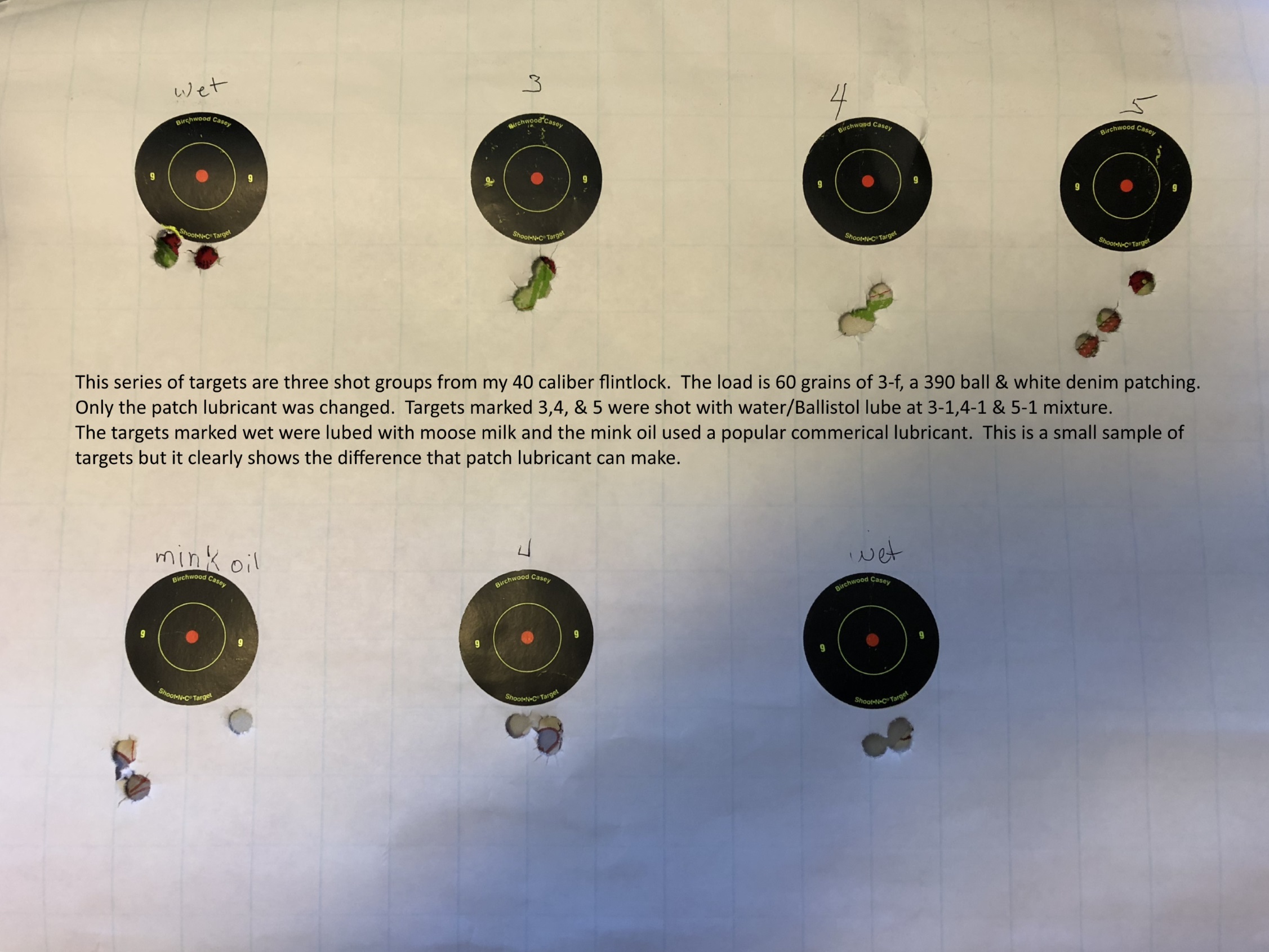

Finding the correct amount of "slickness" for your patch lube

The final variable that affects the accuracy of your load and the size of your group is the patch lubricant. A patch that is slicker than others because it has more lubricant on information technology is non going to have the same amount of friction going out of the butt. Less friction equals less pressure which will equal a lower velocity. That ball with lower velocity will not strike the target in the aforementioned place equally the others. Getting a consequent corporeality of lubricant on every patch equals consistent velocities for every shot.

You can control the amount of lubrication on and in the patch material by using a h2o-soluble oil. Yes, you lot read that correctly. An oil that dissolves and mixes thoroughly with water. The cooling fluids used past machinists to go along the cut caput of their machines from overheating is one of these types of oil. 'Ballistol' is an easy to obtain oil of this type and is available in smaller quantities. This is also one of the ingredients in moose milk recipes and then you lot will need to have some on manus. About good gun stores will have it, if not information technology can be ordered over the internet.

Mix this oil with water and soak your strips of patching in it until they are fully saturated. So lay those strips out apartment on a non-porous surface to dry. The h2o volition evaporate out of the fabric leaving simply the oil. Always lay the fabric strips out flat. If you hang them to dry the water/oil solution will run down the strip leaving more than oil at the lesser and less at the top.

You want the aforementioned corporeality of oil as distributed through the entire strip of patching cloth. Once dry, roll your strips of patching up and store them in a plastic baggie or air tight container such as an empty pill canteen or Tupperware container. With this method you insure that every patch y'all load will have the exact same amount of lubricant, thus eliminating one more variable that affects the accuracy of your load.

To utilise this method to control the exact amount of oil that is distributed in the patching material you will examination different ratios of water to oil. Start by putting ane measure of oil in a glass jar. I apply a 1 ounce measuring cup similar to those used to measure a dose of liquid medicine. And so add 5 measures of water and mix well. Soak i strip of your best thickness of patching material in this mixture, squeeze the excess out of the material back into the jar. Lay that strip out flat to dry and mark information technology 5-1. And so add another measure of water to the mix and soak another strip. Lay it out to dry and mark it 6-1. Go along to add 1 measure of water and soak i strip for a vii-1 mix so forth until you reach a solution of ix-i.

Go back to the range and load your best powder charge and ball combination with the 5-1 mix lubricated strip and burn down a five shot target. Do not add any boosted lubricant to these patch strips. Record all the information on the target and echo with a new target changing just the patching in your load to the strip marked 6-1. Do this until you take shot a v shot target with each strip of patching or until information technology becomes too difficult to seat the ball due to the patch strip being too dry. You lot will once again notice that the groups on the targets show a pattern of becoming smaller and rounder until the load becomes then tight that pounding the ball out of round causes the group to open up up or the load is so tight yous can't go it started in the cage.

The reason this works is because the oil mixes evenly with the h2o and the fabric will only absorb so much of this mixture until it is fully saturated. Once it reaches total saturation the material will take no more than. Allowing the fabric to air dry lets the water evaporate abroad leaving only the oil in the fabric. Mixing more water into the oil causes the fabric to blot more h2o and less oil and so less oil remains in the material afterwards the water has evaporated. In this mode we are able to control precisely the corporeality of oil applied to our patching. Now study your test targets again and there on the target with the smallest group will be written the best mixture of water to oil for your patching in that particular rifle.

This h2o-soluble oil method is admittedly the best, nigh consistently accurate patch lube method in utilise today. Unlike grease or straight oils, you can precisely control how much lubricant is applied to every patch. Different spit or wet lube mixtures this volition not freeze in cold conditions. Information technology volition not dry out if the load sits in the butt during a long hunt or while waiting to take your shot on the range. Information technology won't soak into your pulverisation charge. It will not leave a built upward layer of crud in your bore like some of the concoctions of lip balm, waxes and grease. It will not cause a band of rust inside your barrel if information technology is left in the bore over a period of time. Unlike Crisco, lard, or olive oil, yous don't want to use information technology to cook your breakfast. But you can control precisely the amount of lubrication on your patching in order to find exactly how much "slickness" your barrel requires to shoot its best groups.

Typically, most shooters who use this method will find their best groups to be with a 7-1 or 8-1 mix of water to oil. When I lived in a more than humid area of the country that was the best mix for my guns. Simply afterward I moved to the High Desert of New Mexico with its drier humidity, I found that I had to alter my lube mix to a iii-1 mixture. The 8-i mix that shot then well earlier was now then dry that I could not become that load downward the butt without pounding the heck out of the ball. This is because the corporeality of water that volition evaporate from the patching textile cannot exceed the amount of moisture in the air. In a dryer climate more than water can evaporate from the patching. Then consider that your results may vary according to your local conditions of humidity and adjust the mixture accordingly. All the same, this method will reveal the right amount of lubricant for your conditions and the near accurate loading for your rifle.

Summary

If you accept followed these procedures in the order in which I have listed and explained them your burglarize is at present shooting some very nice groups. This would exist the time to re-test and fine tune your powder charge. At present that you have discovered the ideal combination of ball size, patching thickness, and lubrication your rifle may prove a preference for a slightly increased or decreased amount of pulverisation which might non take been as obvious before. Sometimes a change of ane or 2 grains volition make a discernible departure. You lot should also exam the other powder granulation. Some rifles will evidence a preference for two-F while others shoot amend with 3-F, If you don't test, you won't know.

This system of load development works as well in pistols as it does with rifles. Some smoothbore guns take also shown improvements using this method.

This target was shot off-mitt with my 45 caliber percussion dueling pistol to win the pistol match at a rendezvous. There are half-dozen shots in the grouping.

These 2 targets were shot to confirm my results later I finished this load development arrangement with my xl quotient flintlock. At this point I am set to adjust my sights to move those groups into the X band.

Oops

If your rifle isn't shooting proficient groups yet you may have tried to shortcut the process somewhere or did not fully understand it and managed to overlook the "sweet spot" with i or more of the variables you were testing. I hope not. But if this is the example you need to reread all the information I have given you lot, start over, and follow the system in its entirety.

For this process to produce results it is imperative that you modify merely one variable at a time during your testing. Y'all must as well follow the order I accept given you for testing these variables. Attempting to examination for patching thickness before you detect the sweet spot in your pulverization accuse is non going to show reliable results on your targets. Therefore, y'all fabricated a decision based on faulty information.

Review your bench balance shooting technique. Are you being consistent in all aspects of shooting from a demote? Are y'all resting the barrel in contact with your front end rest for some shots and and then on the wood of the fore stock for other shots? If you are non confident in your bench shooting technique get and lookout man some bench balance shooters in activity. If you don't understand the "why" of what y'all run across them doing wait until a break in the shooting and ask questions.

Re-check your loading procedures. Are you lot using consistent pressure when seating the ball with your ram rod? Are you pounding it down the barrel? Are you wiping the bore between shots? All these details have an event on where the ball strikes the target. Consistency in every activity is critical. Occasionally, even the most experienced bench shooter will pull a shot off of his aiming indicate. When that happens yous are usually aware of information technology. Just don't count that shot in the group on that test target. Simply put another shot on target or post a fresh target and shoot those v shots again.

These are the specality tools and items I similar to use when loading and shooting from the demote and during formal competitions. Some are safety related, some are more precise, and others are for convience.

Ane piece steel range rod with muzzle guide and patch jag.

avaliable from Track of the Wolf

From left to right;

Pulverisation can and abode made capped spout. (fabricated from 2 contumely cartridge cases)

Adjustible pulverisation measure with leveling spout. Patch pocketknife.

Dead accident mallet to start tight loads. (saves hands from brusies)

Custom fit hearing protectors.

Two custom fabricated short starters for use with mallet. (caliber specific and made to seat the ball at the correct depth for ideal patch size when cut off flush with the muzzle.)

Three different caliber starters with muzzle guides. (custom built)

High capiticty capper. (from Ted Greenbacks)

Happy shooter at the Texas State Cage Loaders State Contest.

Some random thoughts on black powder.

Y'all may take noticed that I accept not mentioned utilise of modern substitutes for black pulverization. This is because nothing currently available volition work in a flintlock rifle. A flintlock simply cannot generate enough heat to reliably ignite substitute powders. My early on attempts to use Pyrodex in my traditional side lock percussion rifle was a dismal failure both in accuracy and undecayed ignition. I know of absolutely no competitive shooter using substitute powders in traditional muzzleloading rifles. Whether any of this method applies to substitute powders I haven't a inkling. I have no feel in the utilise of modern shotgun primer, in-line style of rifles and agree no want or interest in them.

I am enlightened that recent ill-conceived authorities regulations take brought an end to the days when one could walk into any sporting goods shop and buy a pound of black powder for as little as $4.00. Accessibility to real blackness pulverisation is a complaint I hear all likewise often and may exist the reason I get and then many questions about bogus powders.

If one is serious about accuracy and dependability in traditional manner muzzleloading rifles real blackness pulverisation is the only way to become. You may likewise accept that you are going to take to contact 1 of the suppliers of black powder, fill out the required paperwork, and pay the hazardous materials shipping fees to get it shipped to your residence. The but other selection is to assemble some friends who shoot muzzleloaders and make a road trip to ane of these distributors to avert paying the additional fees for shipping.

Currently we take several unlike brands of black powder to choose from. I am frequently asked which is best. I know only that the main difference between them, other than toll, is what type of wood was used to produce the charcoal in that particular brand of powder. I know some expert shooters who swear by one make while swearing at another. My observation and simply my observation, is that nigh matches I attend shooters are using Goex or Swiss powders. I am non aware of any scientific testing to prove one powder superior over another. All I see and hear is subjective opinions concerning how clean or dirty a particular make burns or opinions of how consistent the velocities of ane brand of powder is over another. For every negative stance on a particular brand I hear an equal number of positive opinions. Until some testing is performed I tin can only advise that you become a skillful ballistic chronograph and try to sort it out to your own satisfaction.

Two factors which I am certain impact the consistency in burn and velocities in black powder are humidity and powder settling in the container. If one is shooting on a very boiling twenty-four hour period your powder is going to absorb moisture from the air. This leads to increased fouling in your butt that must be dealt with. Information technology as well affects the burn down rate and subsequently the velocity of your charges and this will modify the point of affect on your target as well as having an effect on the size of your group. I know of shooters who, in one case they open up a can of powder to shoot a match, will non use the remaining powder in that container to shoot another friction match the next day or at times even latter on the same day. They volition load from a new container which has non yet been exposed to the humid air.

I of my black powder mentors, an engineer by merchandise and a long time competitor in unlimited weight class, long distance bench balance matches purchases his powder in large quantities and sifts it through three sieves of precisely measured mesh screening. By doing this he segregates all the kernels of pulverization into batches which lucifer precisely in size. His method of screening is more precise than the methods used past the makers of black powder and he claims better consistency in burn rate and velocity past doing this. I am sure of the deviation this makes in the groups fired from his extremely heavy bench burglarize. Still, I would never see this difference in my shooting of targets off hand with traditional weight rifles. I but cannot hold the rifle steady enough for that level of consistency to be noticeable on my targets. Consequently doing that for my application would be wasted time and attempt.

What I accept observed is the change in velocities that occur due to the settling of smaller kernels and particles of powder to the bottom of the container. This is actually magnified when traveling a long distance to a shooting lucifer and the pulverization is transported in your vehicle. The vibrations of the vehicle cause this separation to happen at an accelerated pace. That can of powder now consist of the largest kernels sitting at the top of the tin, the finest dust at the bottom of the can and layers in between which would screen to be sizes from 4-F to equally large as ii-F. If you lot retrieve that won't play the devil with velocities try shooting it over your ballistic chronograph. In an try to negate this outcome, I lay my powder cans on their sides in the vehicle.

The most humorous example of this sifting effect I take witnessed was when a friend who shoots with me in rendezvous matches was trying to diagnose the reason his rifle was printing groups higher and college on successive targets over a three 24-hour interval shoot. He was sure something had gone wrong with the bedding of his barrel. Every bit information technology turned out, this fellow never emptied his pulverization horn. Over the course of several years he simply topped it off afterward every event. This particular event consisted of many more than targets than he ordinarily shot and he was loading powder from near the lesser of his horn. This powder was virtually as fine as 4-F granulation and dust. The load he had his burglarize sighted in for was with 2-F granulation. After that discovery, he always emptied his horn back into a powder can following every issue.

Keeping written notes and information apropos your testing and load development is a fourth dimension and components saver. It also helps you to notice trends when developing loads for several unlike guns. Earlier, when we talked about measuring powder charges I stated that volume measurements produce more consequent results than weighing blackness powder on scales. At present that you know the amount of pulverisation your rifle shoots best, go ahead and fill your measure with that amount and then counterbalance it on your scales. Tape that weight somewhere you won't forget. If you should ever lose that particular pulverisation measure, or wish to make another, yous will exist able to duplicate information technology by weighing out that same amount of powder without having to do all that powder charge testing again. It's rare to find two powder measures that are calibrated exactly the aforementioned. Typically a mensurate marked for fifty grains doesn't actually agree fifty grains of pulverisation by weight. It will also agree slightly more three-F powder than 2-F. After going to all that trouble to find your ideal pulverisation charge don't lose it because powder measures are fabricated inconsistently.

I haven't mentioned percussion caps as a variable in muzzleloader accuracy merely because I have not noticed a reason to conduct testing on them. I typically purchase percussion caps by lots of one k. Usually I employ CCI or RWS caps. If there is whatsoever effect on consistency of groups or bespeak of bear on between the two I have not been able to measure it.

I have been asked virtually the difference in accuracy betwixt cast assurance and swaged balls. The truth is, shooters win matches with both. If one person cast his own balls using good casting technique and the same mold, his cast assurance will be more consistent in size and weight than whatsoever swaged balls yous tin can buy. The just downside with cast assurance is that yous have the sprue to contend with.

Shooters who do non want to get into casting round balls for various reasons will find greater variation in the size and weight of the swaged balls they purchase. This variation might be caused past the corporeality of antimony in dissimilar batches of lead or because the machines in the production line are non all calibrated exactly alike. Regardless, sorting those assurance by weight will remove any disadvantage when competing. When I shot swaged balls in competition I ordered them in lots of 500. Past the fourth dimension I had them all sorted by weight I was left with larger numbers of balls which weighed exactly the same. The lightweight balls I set aside for apply when plinking or to let friends shoot who were interested in shooting a muzzleloader for fun. After I learned to bandage my own brawl I find fewer inconsistencies in them and those that happen to be also light simply go back into the melting pot.

Listing of necessary tools

- Reloaders scales

- Micrometer

- Dial calipers

- Adjustable powder measure out

- Front and rear burglarize rests

- Sand bags

- Metal range rod with muzzle protector

Recipe for moose milk

- Ii ounces of Ballistol

- One ounce of Lestoil concentrated liquid detergent

- Sixteen ounces of distilled or filtered h2o

- Mix well in an empty spray canteen

This makes a very skillful black powder solvent that will not harm the finish on the rifle stock. It can too be used equally a patch lubricant until you attain the indicate of testing the water-soluble oil lube mixture.

How Do You Measure Muzzle Loader Patch Size,

Source: https://traditionalmuzzleloader.com/index.php/developing-an-accurate-load-for-a-black-powder-muzzleloading-rifle

Posted by: gouldtherfull1972.blogspot.com

0 Response to "How Do You Measure Muzzle Loader Patch Size"

Post a Comment